Applications

Housings and covers where damping is needed:- Inverters and converters

- Power electronic units

- Engine covers & oil pans

- Cast covers such as valve covers, chain covers

- Supercharger/intercooler

- Transmissions/flywheel

Benefits

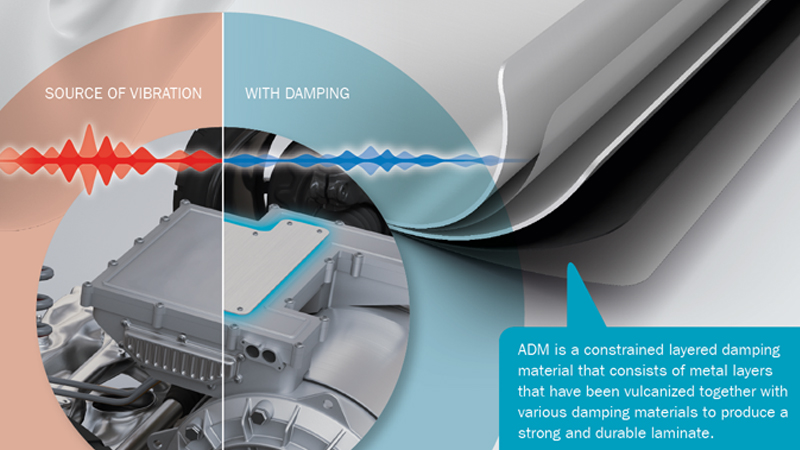

- Reduces structural vibrations and radiated noise

- Damping where it matters

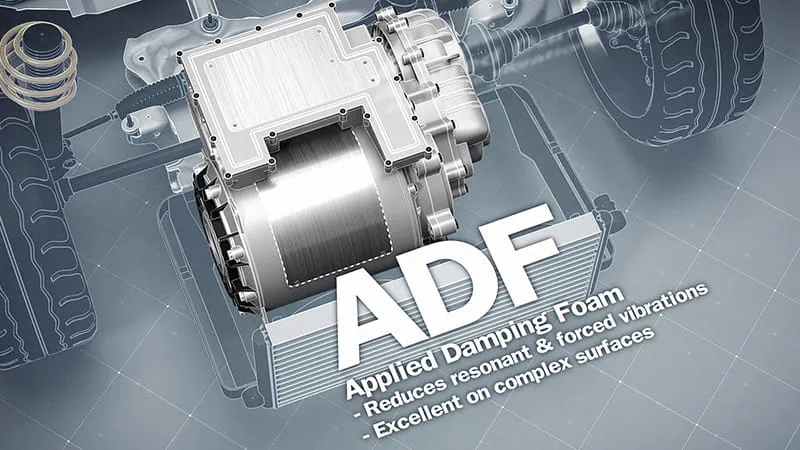

Applied Damping Foam

ADF is a constrained damping material is made of metal and viscoelastic material (VEM) combined with a layer of closed cell foam. Designed to reduce structural-borne noise by combining damping and isolation. It provides superior damping of structure-borne noise of complex 3D surfaces. It combines the functions of damping and isolation tuned to minimize radiation from vibrating surfaces. ADF is especially suitable for stiff structures such as cast iron- or aluminum structures.

Applications

Housings and covers where damping and isolation is needed:

- Electrical motors, Transmissions

- Engine covers

- Super chargers

Benefits

- Can be used on complex surfaces

- Formable to various shapes

- Reduces both resonant vibrations and forced excited vibrations

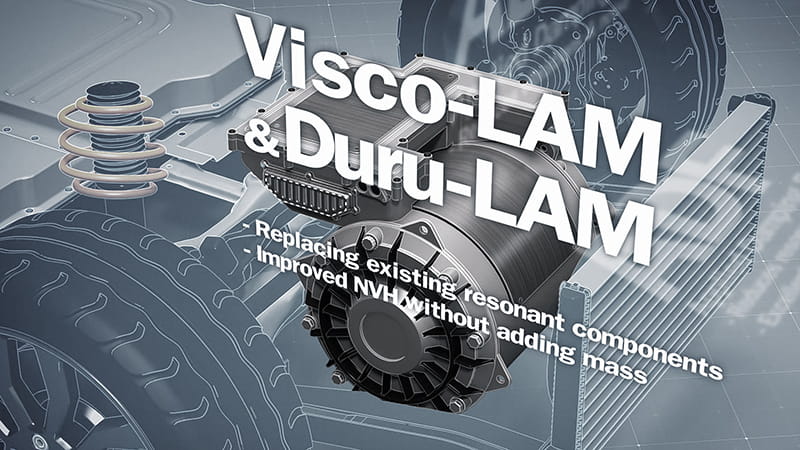

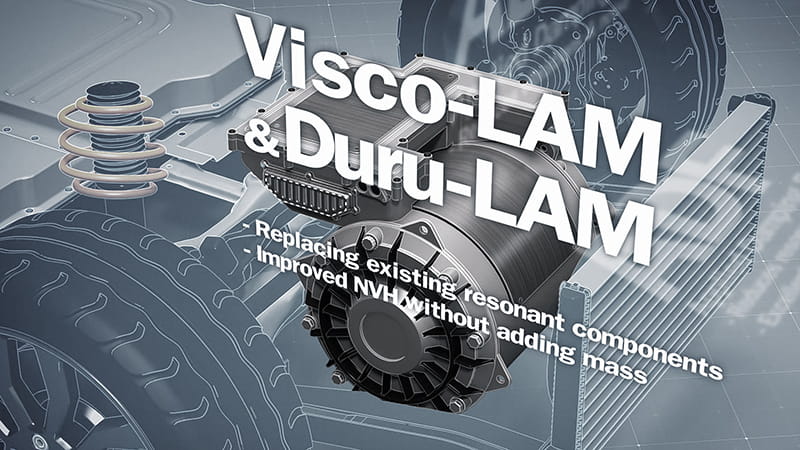

Visco-LAM

Visco-LAM is a sandwich material made of two layers of sheet metal laminated together with an intermediate layer of viscoelastic polymer. Various types of metals and alloys can be used, in different thicknesses, with surface treatment if needed. The material performance can also be optimized by changing the dynamic properties of the polymer.

Visco-Lam is typically used for replacing existing resonant components.

Applications

- Dash panels, floor and roof panels

- Electronic covers, engine covers,

- End covers/access covers, transmission/covers

- Wheelhouse, consoles/brackets

- White goods

- Dual wall concepts, acoustic enclosures

Benefits

- Improved NVH without adding components

- No added mass when replacing existing part

- Weldable options available

- The material combination can be optimized for the specific application

Duru-LAM

Duru-LAM is an excellent choice where a strong and robust material is needed for sound and vibration damping. Duru-Lam is a sandwich material made of two layers of sheet metal vulcanized together with an intermediate layer of elastomer. Various types of metals and alloys can be used, in different thicknesses, with surface treatment if needed. Stands for durability, rubber and laminate. Duru-Lam is used in demanding environments where media resistance and mechanical properties are of high importance.

Applications

- Replacing existing resonant components, for example:

- Baffle plates, splash shields

- Brackets/consoles

- Motor mounts

Benefits

- Improved NVH without adding components

- Superior durability

- Can be used inside engines/transmissions

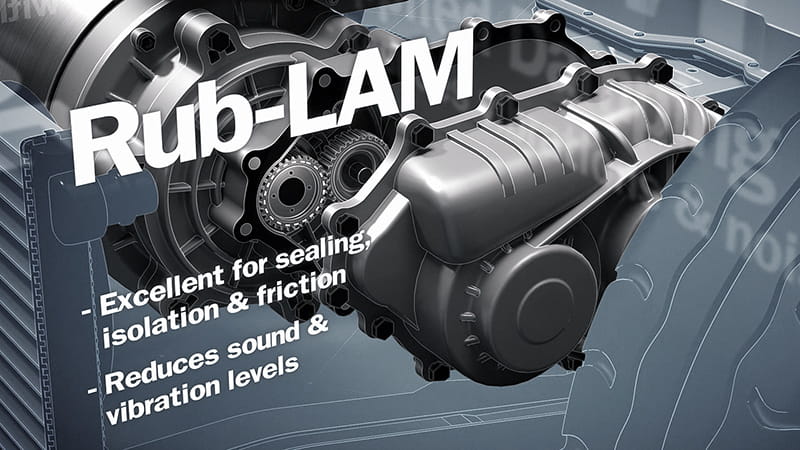

Rub-LAM

Rub-LAM is an excellent choice of material for sealing, isolation, friction as well as sound and vibration damping. Various types of metals and alloys can be used, with surface treatment if needed. The choise of elastomer and thickness is based on the requirements of the application. Rub-LAM is an elastomer to metal sandwich material where the elastomer is vulcanized on one or two sides of the metal layer.

Applications

- Washers, seals/gaskets

- Radial dampers for gear wheels and pulleys

- Steering systems

- Ceilings, flooring

Benefits

- Improved NVH

- Durable in stamping and forming

- Sealing properties

- Various friction levels available